Operating -

Tank wash / Agitator

3) Clean water will then be drawn out of the tank and will be pumped through the rotary flushing nozzles in the tank.

Engine tickover speed is all that is required to operate the rotary nozzles for a good cleaning action. High engine/pto speeds may damage the rotary heads.

For the best cleaning effect it is

recommended that the tank and lines be flushed through twice, so only

draw half of the clean water out of the tank for now.

4) Whilst the water is being drawn out of the clean water tank, turn the main pressure valve to the chemical inductor position for a few moments to flush clean water through the chemical inductor. Also operate the other valves on the inductor to flush through all the other pipes and then turn the main pressure valve back to the tank wash position.

5) When you have drawn the required

amount of water out of the clean water tank, turn the suction valve

back to the spray/circ position, and and the pressure valve

back to the spray/circulation position.

6) Turn all the boom switches off

and the master sprayer switch on for a few moments - this will flush

out the return pipes back to the tank. Turn the master switch off and

the boom switches back on again.

7)You can then proceed to spray the

washings out on to your under-dosed area of the field.

8) When you have finished, the whole procedure should be repeated with the second half of the clean water.

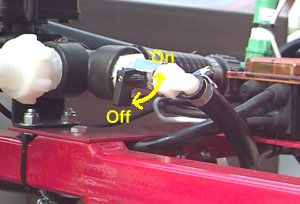

Agitator

A booster agitator is fitted inside

the spray tank for extra agitation if required. It is recommended

that it be used when spraying chemicals that are held in suspension

or are prone to settling out. It is operated by moving the valve

shown in the picture below.

|

|

|