Operating -

Tank wash system

Tank washing system

|

The optional tank wash system

allows the tank and spray lines to be rinsed out and the washings

disposed of in the field.

If you are changing chemicals and

crops, and there is a potential danger of crop damage being caused by

the tank not being thoroughly cleaned, then it is recommended that a

further full wash is carried out with a cleaning agent by

conventional methods afterwards. |

|

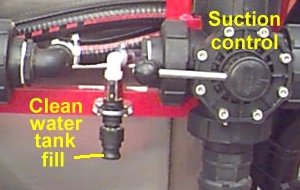

The clean water tank holds 10% of

the main tank volume. To fill the clean water tank, connect a hose to

the small valve in between the main control valves. Only clean

water should be used.

Recommended washing procedure

The following procedure is

recommended to ensure that your crops are not overdosed and you end

up with a relatively clean sprayer using the minimum amount of water

and, of course, minimising the possibilities of any pollution.

When you spray a field in which you

know you are going to use the tankwash afterwards, the area of the

field where you intend to spray the washings should be under-dosed by

approximately 15%. The area required can be calculated as follows:

½ wash tank volume ÷

Application rate (l/ha) e.g. 75 ÷ 200 l/ha = 0.375 hectares.

The easiest way to achieve this to

increase your speed by 15%. e.g. from 10 to 11.5 kph. Choose a smooth

area of the field and before setting off reset the trip area meter on

the RDS. You can then simply watch the area meter until you have

covered the required area and then slow down again. If you have a

variable speed PTO you will need to set it in constant mode. If you

have an automatic rate controller you will need to alter either the

application rate programmed into the unit or switch it into manual mode.

Washing the tank

1. As you finish

spraying, empty the tank of as much chemical as possible and switch off.

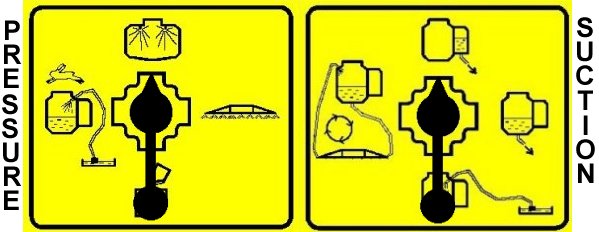

2. Turn the main

sprayer pressure control valve to the tank

wash position. and the main suction valve to the clean water

position. (see below)

Valve positions for tank washing