Operating -

Chemical Inductor

Chemical inductor

The chemical inductor hopper is

fitted to the nearside of the spray tank. It works on the venturi

principle. i.e. A high pressure flow from the pump passes through a

Venturi tube underneath the hopper. This creates a drop in pressure

as the flow passes into the larger bore outlet hose. This in turn

"sucks" the contents out of the hopper and "blows"

it straight through the outlet hose into the tank.

The advantage of this system is

that no neat chemical has to pass through the pump and the

"sucking" and "blowing" effect mixes and

disperses liquid and powdered chemicals in the spray tank without pre-mixing.

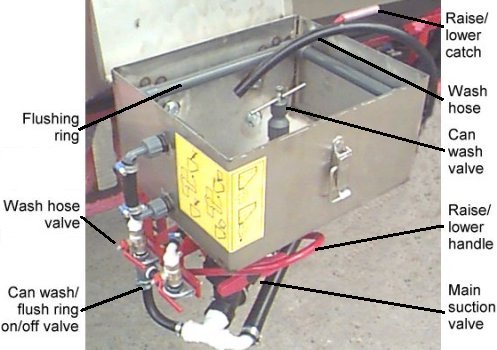

The hopper is fitted to a bracket

that can be raised and lowered by lifting the catch shown below. This

is particularly useful when the machine is fitted with high clearance wheels.

A container flushing nozzle is also

built into the hopper which can be used to flush out empty chemical

containers with the washings going straight into the hopper.

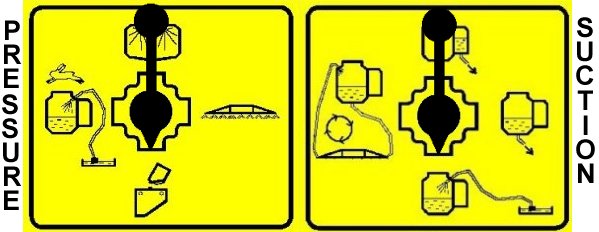

The chemical inductor can be used with the suction valve in any position (except purge) but the pressure valve must be in the Chemical Inductor position. The most common position for the suction valve is for it to be used in the water self-fill position (see diagram below) - This is the best time to add chemicals to the tank - i.e. when clean water is being drawn in whilst filling.

Normal Valve

positions whilst using inductor