|

PTO controls

Please see tractor unit manual for

details on the PTO system.

NB. Please remember it is

recommended that the PTO be run at as low a speed as possible with

sprayers that are fitted with high capacity pumps. i.e. 350 rpm for

5/6 cyl pumps & 400 rpm for 4cyl pumps. (see tractor manual for

more detail). However please ensure that you have enough liquid flow

for agitation with the pump running at your selected speed.

Spray tank

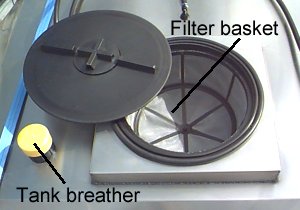

Tank lid

The tank lid (fig. 2) is a screw on

type and can be opened by turning anti-clockwise.

Filter basket

There is a filter basket inside the

tank lid. If you add chemicals directly into the spray tank always do

so through this filter and make sure that the chemical is washed

through the filter with a hose pipe.

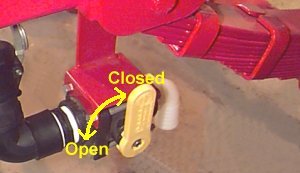

Tank drain (stainless tanks)

The spray tank is fitted with a

remote drain tap mounted on the side of the tractor unit chassis.

Turn the tap anti-clockwise to drain.

Tank drain (fibreglass tanks)

The spray tank is fitted with a

remote tank drain tap on the top of the spray tank. To drain the tank

contents turn the valve anti-clockwise. When closing the valve it is

important not to over tighten it.

The valve plug can be removed by

unscrewing the tap and withdrawing the rod up to the top of the tank.

The plug can then be pulled off the end of the rod for cleaning.

Please remember to take into

consideration any environmental regulations before draining the tank.

Ensure the drain tap is closed

before filling the tank.

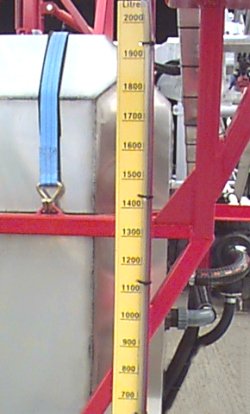

Tank sight guage

A sight level

guage is fitted to the front near side of the spray tank. It is

important that the machine should be stood on level ground for it to

read accurately. Even a slight slope can cause significant inaccuracies. |

Tank

lid & filter basket

Tank

lid & filter basket