|

Handbrake

Adjustment

1. Chock the

wheels and ensure the brake lever is off.

2. Raise one of

the rear wheels clear of the ground and support the axle with an axle stand.

3. Tighten the

adjusting bolt (3 right) until brake drum will not rotate by hand.

4. Slacken the

adjuster by turning it 1.5 turns anti-clockwise and ensure the drum

rotates freely.

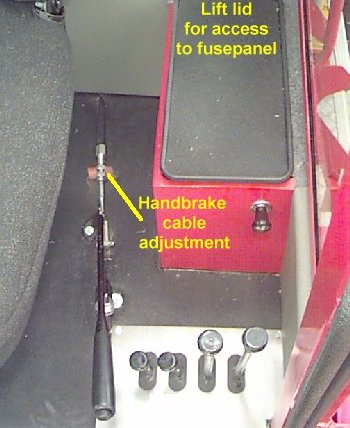

If the actuating

cable becomes slack, the free play can be taken up by adjusting the

cable fitting in the cab (see right).

Lubrication

A grease nipple is

also fitted into the operating cable approx 300mm up from the brake

calliper. This should be greased every 50 hours.

Shoe replacement

If the adjuster

reaches the end of its travel, the brake shoes will need replacing.

To do so the rear

prop shaft will need to be removed and the drum will then slide off

after slackening off the adjuster.

The drum should be

removed every 600 hours to clean the brake. If you are working in

very wet and muddy conditions or if you are spreading a lot of

fertiliser then it may require cleaning every 300 hours.

Foot brakes

The brake master

cylinder is situated in front of the cab and behind the radiator. Top

up with ‘Universal’ brake fluid to between the 'max' and

'min' marks on the reservoir.

The linkage from

the brake pedal to the master cylinder should be lubricated

regularly. There is also a grease nipple on the lower brake linkage

pivot shaft under the cab floor.

The brakes are all

self adjusting discs and only need to be checked for wear

periodically. Have the pads replaced before they get right down to

"bare metal".

If you use your

PHANTOM to spread a lot of fertiliser, inspect the metal brake pipes

regularly for signs of corrosion and replace if necessary. |