|

Fuel system

It is particularly

important to keep the fuel system well maintained - If even only

slight traces of contamination or water are allowed to get past the

filtration system and into the injection pump, the engine performance

will be seriously affected and serious damage will be caused to the pump.

Fuel tank

The fuel tank

holds approx. 19 gals (86 litres). Use clean diesel fuel only. Always

fill the tank at the end of the days work to avoid condensation.

Drain the diesel tank periodically. (At least every 300 hrs) Take

care to ensure the cap is correctly fitted after filling and when

washing off do not direct a pressure washer directly at or under the filler/breather.

Water/sediment trap

A water

trap/sediment bowl is fitted in the suction line between the tank and

fuel filter. The glass bowl should be checked weekly for any signs of

water or sediments. The glass bowl should be removed, emptied and

cleaned before it gets half full of water. When the bowl is removed

you will also find a gauze mesh filter under the head unit which

should also be removed and thoroughly cleaned. Failure to keep this

mesh clean will result in loss of engine power. When replacing the

bowl take care not to overtighten the thumbscrew.

Draining fuel filter

The fuel filter

unit should also be drained regularly (every 50 hrs). To do so

slacken the valve underneath the filter assembly to allow any

accumulated water to drain from the filter.

Replacing fuel

filter element

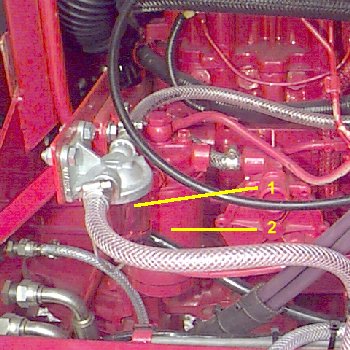

1.

Ensure filter head (1) area is clean.

2.

Drain fuel from fuel filter.

3.

Using a strap wrench, unscrew the filter(2) and catch the fuel

released in the container.

4. Wet

the seal of the new filter (3) with diesel fuel and screw the filter

into position and tighten.

5. Ensure

the drain tap (4) at the base of the filter is closed. |

1. Water /

sediment trap

2. Fuel filter

Fuel filter assembly:

-

Filter head

- Filter element

- Sealing ring

- Water drain

- Air bleed screw

|