Operating -

Balance return valves

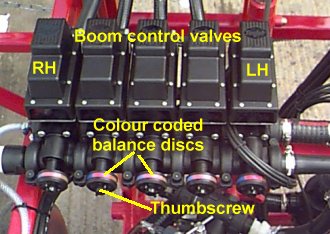

Boom balance return valves

NB Balance return valves may not

be fitted to all machines with automatic spray rate controllers.

Whilst spraying, if a boom section is switched off, the flow of liquid is returned to the tank through its respective balanced return valve. When correctly set these valves ensure that the spraying pressure remains constant no matter how many sections are turned on or off.

They have no effect whatsoever when

all the boom sections are switched on. Each valve only affects the

spraying pressure when its respective boom section is switched off.

These valves should be re-set whenever you change jets although if you are only changing to a jet one size up or one size down you are unlikely to see a significant fluctuation in the spraying pressure. However, if you are changing from a very small jet to a very large jet and you do not adjust the balanced returns, you will see a marked increase in the spraying pressure when you switch a boom section off.

It is extremely important to

ensure that these valves are set accurately if your sprayer is fitted

with a flow based automatic controller such as the RDS Delta

3 or Pro series.

If they are not then the actual application rate can vary from the

target and indicated rate by a significant amount when you are

spraying with one or more sections switched off.

|

TeeJet boom valves |

|

Setting up

Before using the

balance return valves each coloured segment on all the valves must be

set up to match each different nozzle that you use.

NB They are not normally pre-set because of the varying flow rates of the many different nozzles that are available. You must therefore set them up as follows BEFORE applying chemical.

The valves should only be set up when the sprayer is clean and whilst spraying out clean water - a full tank may be required to set all the colour segments up.