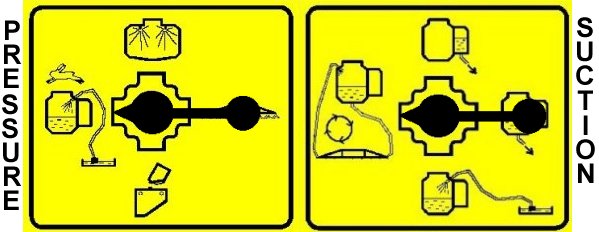

Operating -

Quick fill / Purge

|

Quick fill (optional) An optional quick-fill system can be fitted to allow filling from a external, high capacity pumped bowser system.

A camlock

connecter is fitted to a 2" ball valve situated near the main

control valves on the near side of the sprayer. A drop pipe is fitted

into the tank so liquid is pumped in below the level in the tank to

avoid foaming. |

|

Purge system (optional)

The purge system is fitted to allow air and clean water to be purged from the boom spray lines and to fill them with fresh chemical ready for spraying. It is only necessary to use it when starting from scratch and when changing chemical.

The system is

controlled by the main suction valve on the near side of the sprayer.

When this is set to the Purge position it does several things:

a) It opens a

microswitch to change the position of an additional electric ball

valve which in turn connects the sprayer control manifold to the main

suction valve.

b) It opens a port

in the main suction valve to connect the manifold directly to the pump.

c) It opens all

the electric boom section valves.

e) It isolates the

flowmeter (if fitted) to stop it recording additional volume on the

spray monitor.

Recommended procedure

After filling the

spray tank with water and chemical and after allowing sufficient time

for it to agitate and mix, simply turn the two main valves to the

positions shown above and wait for approximately 30 seconds. This can

normally be done whilst spray cans etc are tidied away.

Liquid is then

drawn backwards through the spray lines and sprayer controls and is

directed back into the tank. It is drawn into the spray lines through

a series of non-return valves which block the pressure once the flow

is reversed again for spraying.

When spraying is

commenced you can start moving straight away knowing that the piping

system is full of chemical.