|

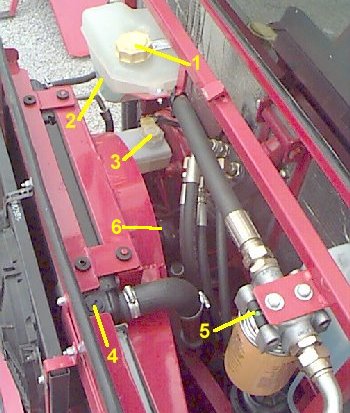

Hydraulic oil

Ensure the

hydraulic system is kept clean. Be careful when refilling tank. Do

not direct high pressure hose at filler/breather cap. Oil level

should be kept to top of level/temperature gauge. Use good quality,

clean hydraulic oil for topping up only ( I.S.O VG 68 ). Do not use

universal oils. The oil should always look clear and clean - If there

are any signs at all of cloudiness or "milkiness" the oil

should be changed.

Oil filter

Change return line

filter when indicator on filter unit turns red or at least every 12

months. If excessive oil contamination is evident the oil should also

be changed and the suction filter (inside tank) should be removed and

washed out. If this filter is removed ensure that no contamination

gets inside the suction pipe or into the inside of the filter.

Oil cooler

If an oil-to-air

cooler is fitted in front of the engine radiator, ensure that it is

kept perfectly clean along with the radiator behind it at all times.

Failure to do so will lead to overheating of the hydraulic and/or

engine cooling systems.

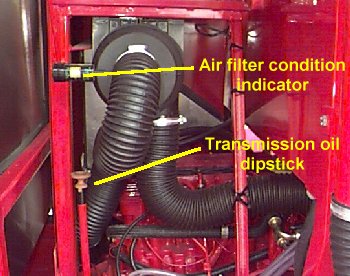

Air Cleaning System

The PHANTOM is

fitted with a Filter Minder air restriction indicator. This has a

scale which shows when the air cleaner is getting dirty. It is fitted

on the side of the air filter assembly. It is reset by pressing the

rubber button on the end of the indicator. Avoid opening the air

filter assembly until the gauge indicates 18’’ air

restriction. Service BEFORE the yellow indicator reaches the red line.

When the air

filter element does need servicing, replace it with a new one. Do not

attempt to clean it. The condition of the air intake hoses should be

checked regularly for signs of wear or damage and should be replaced

if necessary.

Dump Valve

The dump valve is

situated on the end of the filter housing (see right). Squeeze the

valve open to release any accumulated particles every 50 hrs. |

5.

Hydraulic filter condition indicator

5.

Hydraulic filter condition indicator